What are the main structural components of a hydraulic winch?

2025.01.08

2025.01.08

Industry News

Industry News

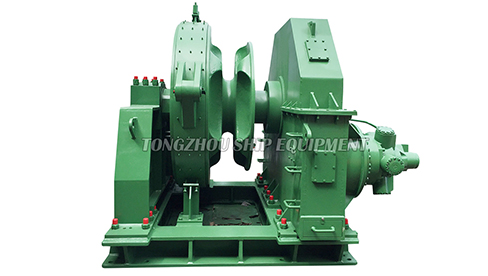

A hydraulic windlass is a crucial piece of equipment used primarily on ships, offshore platforms, and other marine applications where heavy lifting and anchoring tasks are necessary. Understanding the key structural components of a hydraulic windlass is essential for both its operation and maintenance.

Hydraulic Motor

At the heart of any hydraulic windlass is the hydraulic motor, which drives the entire system. The motor converts hydraulic energy, supplied by the hydraulic pump, into mechanical energy, which rotates the drum or drum components of the windlass. Hydraulic motors are selected based on the required torque and speed for the windlass's application.

Hydraulic Pump

The hydraulic pump is responsible for pressurizing the hydraulic fluid, providing the necessary power to the hydraulic motor. The pump ensures that a consistent flow of hydraulic oil is maintained under pressure to operate the windlass efficiently. The type of pump used can vary, with gear pumps and piston pumps being common choices for such systems.

Windlass Drum

The windlass drum is the central component where the anchor chain or rope is wound. This drum is usually made of high-strength steel or other durable materials to withstand the heavy loads and harsh environmental conditions encountered at sea. The drum rotates as the hydraulic motor drives it, either pulling in or letting out the chain or rope.

Chain Pipe or Wildcat

The chain pipe, or wildcat, is a grooved drum that engages with the anchor chain. It allows the chain to be wound and unwound without slipping, providing a secure grip on the chain. The design of the wildcat depends on the type of chain and the windlass's intended application. It plays a critical role in controlling the anchor's deployment and retrieval.

Brake System

The brake system is an essential safety feature in a hydraulic windlass. It ensures that the windlass can be stopped and held in place when necessary, preventing the anchor from slipping or running out of control. The brake system typically uses a combination of mechanical and hydraulic components to engage and hold the drum in position when not in use or under heavy loads.

Bearings and Shafts

The bearings and shafts are critical for the smooth operation of the windlass. Bearings reduce friction between moving parts, ensuring efficient movement and minimizing wear and tear. The shafts transfer the rotational force from the hydraulic motor to the drum, and they must be designed to handle substantial stresses and rotational forces.

Control Panel

The control panel is the interface through which operators control the hydraulic windlass. It allows users to adjust the speed, direction, and operation of the windlass. Modern control panels may feature electronic controls, allowing for greater precision and automation in windlass operation.

Hydraulic Reservoir

The hydraulic reservoir stores the hydraulic fluid required for the system. It ensures that the hydraulic pump and motor are supplied with an adequate amount of fluid to operate effectively. The reservoir is typically equipped with filters to keep the fluid clean and free from contaminants.

Hydraulic Lines and Valves

Hydraulic lines and valves control the flow of hydraulic fluid within the system. These components allow for the regulation of pressure and fluid direction to the hydraulic motor and pump. Proper maintenance of hydraulic lines and valves is crucial for the efficient operation and longevity of the windlass.

Structural Frame

The structural frame provides the physical support for all the components of the hydraulic windlass. It is designed to withstand the heavy loads and dynamic forces experienced during operation. The frame is usually constructed from high-strength materials, such as steel, to ensure durability and stability.

English

English  عربى

عربى  中文简体

中文简体